Herm Machinery will go to ETHIOPEX – Ethio Poultry Expo 2025

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29The pet food production is assigned to pet food (including dog food, cat food, etc) with unique shapes, tastes, and colors, and adapts to scientific nutrition ratio and easy to digest and other features to adapt to the ever-growing pet food market. Taste of varied shapes and meet the needs of all kinds of pet food.

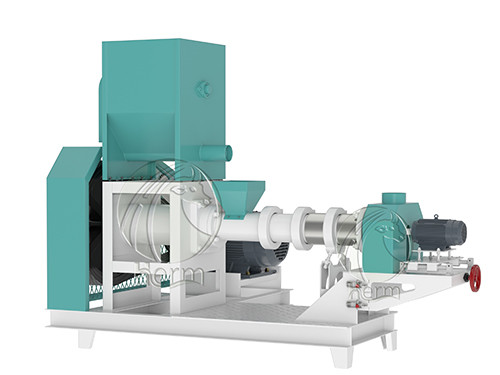

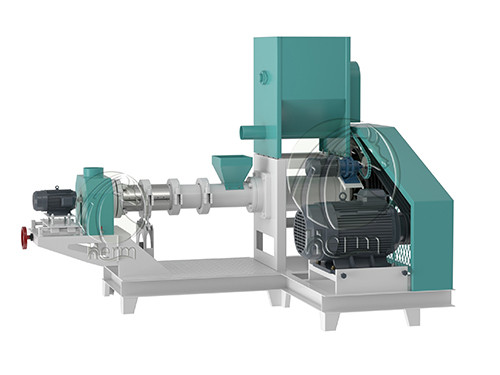

Our pet food production line consists mixing machine, pet food extruder, air cooler machine, drying machine, seasoning line, etc. Reasonable structural design, special materials, and self-cleaning performance ensure the stability of the machine and facilitate maintenance.

1. What is the Pet Feed?

Pet feed refers to the products produced by industrial processing for direct consumption by pets, also known as pet food, including pet compound feed, pet additive premix feed, other pet feed, etc.

2. What Raw Materials Can Use in the Pet Food Production Line?

Pet food mainly uses protein and fat as raw materials, including wheat, soybean meal, rapeseed meal, rice bran, bran, blood meal, bone meal, meat meal, oil, antibiotics, vitamins, etc.

3. What kind of Feed This Pet Food Production Line Can Produce?

It can produce dog food, cat food, and other pet food with different shapes, tastes, and colors and also can produce aquatic feed floating feed, mackerel feed pellets, goldfish feed pellets, shrimp feed pellets, crab, mud, bullfrog and other feeds and foods.

4. Why Choose Our Pet Food Production Line?

Widely Applications: This animal feed pellet mill plant can make feeds for dogs, cats, and other pets with different shapes, tastes, and colors, and also can produce aquatic feed floating feed, mackerel feed pellets, goldfish feed pellets, shrimp feed pellets, crab, mud, bullfrog feed with different sizes in diameter.

Low Installation Cost: Our pet feed production line is carefully designed according to the on-site survey of the production site and customer requirements, in line with the principle of “economical and practical”. It comes with detailed installation and commissioning instructions, and it is easy to install the machine, and you can use it immediately after the machine is installed.

Low Production Cost: The animal feed factory only needs several production workers to complete the production operation. With less labor and lower production costs, your profits will increase.

5. What we can do for you?

We can provide the project design, layout design, flow chart, feed-making machine manufacture, the project installation and commission, your staff training, after-sales service, etc. Also, our professional install team will serve you if you need it.

Typical raw materials used in pet food processing include grain meal, vegetable protein, minerals, and vitamins, and in some cases meat or fish meal and fresh meat.

The dried material enters the pre-conditioner for steam hydration. The mixer mixes the ingredients and ensures the steam, moisture, and ingredients are properly mixed.

Pre-treatment produces partial gelatinization of the starch and a polymeric structure. The par-cooked mixture is then sent to a twin-screw extruder with precise control of shear, internal temperature, pressure, moisture, and residence time to achieve optimal starch gelatinization without loss of food quality.

At various stages of processing, liquid or vapor can be injected through ports in the extruder barrel. Degassing can be done at this stage using exhaust packing.

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd will also participate in AGROWORLD...

25-10-28

Ethiopia’s growing livestock sector, particularly in sheep and goat farming, has created a substantial demand for high-quality animal feed. With t...

24-11-12Let us be your solutions source.