Herm Machinery will go to ETHIOPEX – Ethio Poultry Expo 2025

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

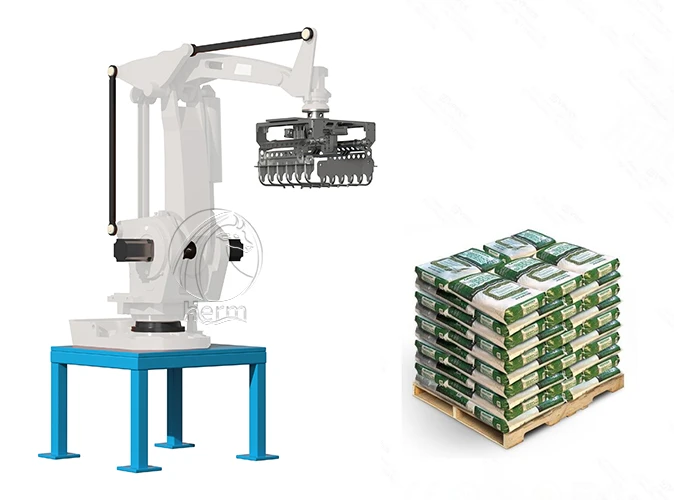

25-10-29The palletizing robot is an advanced automation system designed to replace manual labor in end-of-line packaging, providing efficient, stable, and reliable palletizing for bags, cartons, and various packaged products. With high-speed operation, precise positioning, and consistent stacking quality, it significantly improves production efficiency while reducing labor intensity and operational costs.

Widely used in feed mills, premix plants, pet food factories, grain and oil processing, chemical industries, and logistics centers, the palletizing robot has become essential equipment for modern automated production.

Our palletizing robots are specially engineered for the feed packaging industry, offering superior adaptability, high flexibility, and stable long-term operation.

Our palletizing robot adopts a 4-axis or 6-axis industrial robotic arm driven by a high-performance servo system and advanced motion control software. Equipped with a user-friendly touch-screen interface and intelligent control program, it ensures fast, accurate, and stable palletizing for different bag types and product sizes.

The system integrates seamlessly with automatic packing scales, bag sewing machines, metal detectors, checkweighers, bag flatteners, conveyors, automatic pallet dispensers, and stretch wrappers to establish a fully automated packaging-to-palletizing line.

Multiple palletizing patterns are preconfigured in the system, enabling quick changeover for different formulas or product specifications—ideal for feed plants with frequent product switching.

A specialized gripper is designed according to feed bag characteristics such as soft texture, variable shape, and high weight. Whether handling woven bags, kraft paper bags, laminated bags, plastic bags, or cartons, the robot ensures reliable gripping without slipping or bag damage.

Our system is enhanced in structure, software logic, dust protection, and bag-handling algorithms specifically for feed industry environments, making it ideal for intensive, continuous operation.

Wide anti-slip gripper ensures firm gripping of soft or irregular woven bags.

Intelligent pressure adjustment prevents bag deformation, tearing, or slipping.

Integrated shaping system flattens bags for uniform stacking.

Automatic compression guarantees neat, stable, and forklift-friendly pallets.

Key components are sealed to resist dust infiltration, a common issue in feed plants.

An independent filter system inside the control cabinet extends equipment lifespan.

Preloaded palletizing programs for various feed bag sizes and weights.

One-touch switching requires no manual adjustment of the gripper.

Fully compatible with our packing machines, conveyors, sewing systems, and pallet dispensers.

Optimized for uninterrupted, high-speed, automated bagging and palletizing flow.

Up to 800–1200 bags/hour, depending on bag type and configuration.

Automatic adjustment ensures stable, safe handling of various soft or hard bags.

Supports column stacking, cross stacking, interlocking, mixed patterns, and more.

Touch-screen operation, production statistics, error warnings, and remote diagnostics.

Replaces multiple workers and ensures non-stop, consistent palletizing.

Fits different workshop spaces and supports customized line design.

Animal feed (poultry feed, livestock feed, ruminant feed, aqua feed)

Premixes and additives

Pet food

Grain processing

Flour, rice, chemical powders, and granular materials

Robotic palletizer (4-axis/6-axis)

Customized gripper

Bag infeed conveyor

Bag flattening conveyor

Pallet dispenser

Palletizing station

Finished pallet output conveyor

Automatic stretch wrapper (optional)

Remote monitoring system (optional)

Q1: What types of bags can the robot handle?

Woven bags, kraft paper bags, laminated bags, PE bags, cartons, and more.

Q2: Does it support multiple products?

Yes. It allows fast changeover between different bag sizes and weights.

Q3: Can you provide a customized solution?

Absolutely. We customize layouts, grippers, and configurations based on your plant design.

Q4: How long is the service life?

Typically 10+ years, with low maintenance requirements.

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd will also participate in AGROWORLD...

25-10-28

Ethiopia’s growing livestock sector, particularly in sheep and goat farming, has created a substantial demand for high-quality animal feed. With t...

24-11-12Let us be your solutions source.