Herm Machinery will go to ETHIOPEX – Ethio Poultry Expo 2025

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

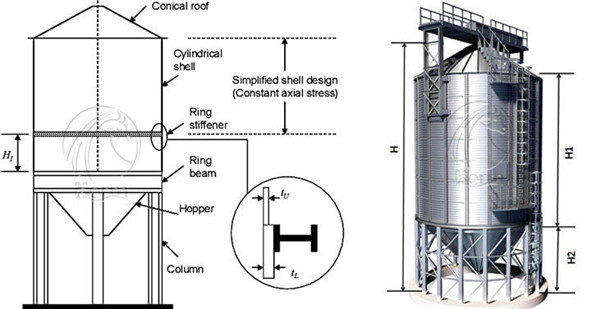

25-10-29Hopper silos are widely used in applications requiring routine low-volume storage and quick cleanup, reducing energy and labor costs for material handling. The hopper bottom bin, also known as the grain hopper bin and the hopper bottom storage bin refers to a silo with a tapered bottom. Typically, most material storage requires the use of hoppers in silos.

According to customer requirements and conditions, the shape of the hopper or cone is specially designed to meet the needs of storing products. For some products, such as food and grains, hazards and safety concerns need to be eliminated. It is designed for agricultural, industrial, commercial, and strategic applications such as large farms, inland storage facilities, grain terminals, and grain-based factories such as flour mills, feed mills, rice mills, oil mills, and biofuel facilities.

Make a Quick Inquiry Now !Our hopper bottom silos contain full drainage. The configuration of the hopper bin depends on the type of material to be stored. Generally, granular products require a 45。 cone bottom silo, while powders or other difficult-to-flow materials are suitable for storage in a 60。 cone bottom silo. If complete drainage is required, the bottom hopper silo is your only option.

1. Our different model's hopper silos, which diameters vary from 3m to 13m and capacity from 300 to 1500tones.

2. High galvanization and perfect quality accessories for a longer corrosion protection guarantee. Galvanized steel of 275g/m2, 450g/m2, or 600g/m2 can be selected according to the environmental conditions of the silo.

3. Standard design hopper angles are 45。 and 60. It can also be manufactured according to natural conditions such as silo diameter, grain storage characteristics, warehouse wind, earthquake, and snow load.

4. The inner surface of the hopper plate features mushroom head bolts to ensure maximum cleanliness within the silo.

5. Smooth-walled hopper silos for non-free-flowing materials are available upon request.

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd will also participate in AGROWORLD...

25-10-28

Ethiopia’s growing livestock sector, particularly in sheep and goat farming, has created a substantial demand for high-quality animal feed. With t...

24-11-12Let us be your solutions source.