Herm Machinery will go to ETHIOPEX – Ethio Poultry Expo 2025

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29Herm machinery high-quality fish feed pellet mill plant can produce various fish feed pellets, including grass carp feed, herring feed, carp feed, trout feed, tilapia feed, salmon feed, catfish feed, etc. The raw materials of the complete fish food plant production line include fishmeal, homemade fishmeal, alcohol masterbatch, soybean phosphatide, soybean meal, peanut meal, shrimp flour, sub-powder, wheat gluten meal, vegetable oil, etc.

Make a Quick Inquiry Now !The final pellet produced is between 0.5 mm and 12 mm. For example, grass carp 0.8-6.0mm pellet, herring 0.5-6.0mm pellet, carp 0.8-5.0mm pellet, bream 0.5-3.5mm pellet, rainbow trout 0.8-3.0mm pellet, trout: 0.8-3mm pellet, tilapia: 0.8- 4mm pellet.

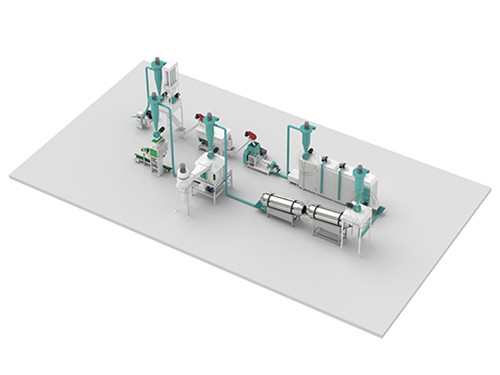

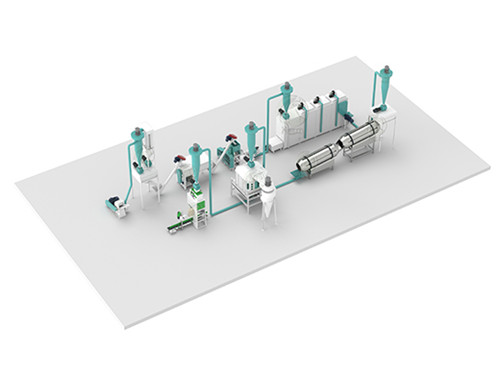

The complete fish feed production line includes a feed grinder, feed mixer, feed dryer, feed cooler, oil spray machine, and packing machine which are connected by conveyors or elevators. The feed pellet can float on the water for 12 hours at least. Adjusting the feed formulation also can make a sinking feed pellet. The pellet size is from 1mm to 12mm by changing the molds.

The products can have different shapes, unique flavors, rich nutrients, and fine textures to meet the different eating habits of animals. With Super automation control and high production efficiency, this fish feed production line is the best choice for medium and big-sized feed mills and breeding farms.

Feed Grinder: mainly used for grinding all kinds of raw materials like soybean, maize, etc.

Feed Mixer: mainly used to mix all kinds of raw material evenly, such as wheat meal, corn meal, sorghum meal, bone meal, meat meal, and so on, it also can mix other micro-ingredients such as vitamins, amino acids, trace elements, and other feed additives.

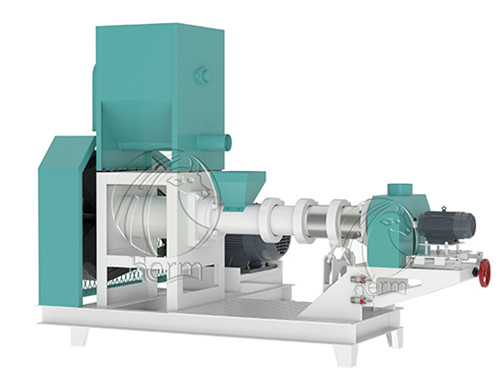

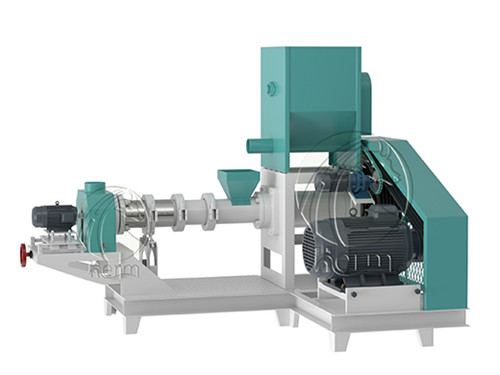

Dry Type Fish Feed Making Machine: it is the main machine to make the raw materials into feed pellets.

Feed Dryer: to reduce the moisture content of the feed pellet.

Feed Cooler: low the temperature after pellet drying with a higher temperature.

Oil spray machine: use to spray oil onto the surface of the feed pellet. Which is delicious food that can attract the fish to eat the pellet. Second, it is better for storage.

Pellet Packing Machine: packing the finished feed pellet into bags, and 1-50kg per bag, is more convenient for storage and transport. The process includes filling, weighing, and sealing.

Feed conveyors and elevators: which are used between machines. It can save labor and make the line more automatic.

We can design and supply different capacities of the complete line according to customers’ requirements. Usually have 200kg/h, 350kg/h, 500kg/h, 800-1000kg/h, and 2000kg/h.

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd will also participate in AGROWORLD...

25-10-28

Ethiopia’s growing livestock sector, particularly in sheep and goat farming, has created a substantial demand for high-quality animal feed. With t...

24-11-12Let us be your solutions source.