Herm Machinery will go to ETHIOPEX – Ethio Poultry Expo 2025

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29

Name: Animal Pellet Feed Factory

Country: Ethiopia

Date: 2022.11.20

Capacity: 8-12ton per hour

Feed Type: chicken feed and cattle feed

Factory size: 70*50m

Customer's Main Raw material: Corn, wheat, Soybean Meal, and other Grain

Dosing system: 8-bin fully automatic batching system

Packing System: fully automatic packing system

Boiler System: Including boiler and all supporting systems

Customized Scheme: It's a customized scheme for our customer

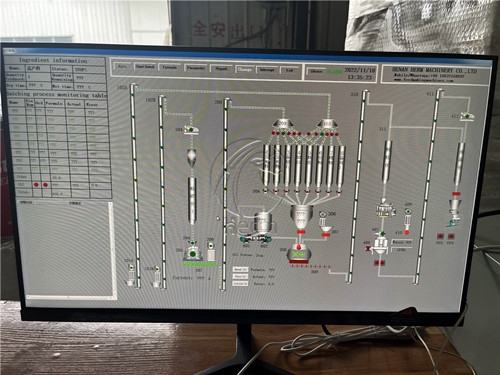

PLC Control System: Contains fully automated PLC control system

Main Machines in the Complete Line: feed hammer mill, feed mixer, feed pellet making machine, packing machine, etc, it is one set full automatic control system

Our company provides drawing details:

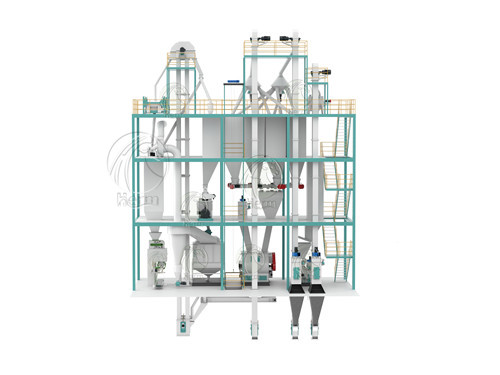

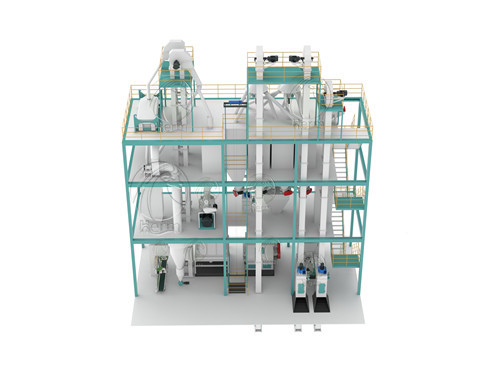

1. Flow Chart

2. 3D layout design drawing

3. Foundation construction drawings

4. Operating instruction

5. Produce construction design drawings;

6. Complete set of steel structure drawings and steel material list;

7. Workshop floor plan and cross-sectional layout

8. Steel structure construction drawings;

9. Detailed steel structure drawings and materials list;

10. Diagram of floor;

11. Roof and wall reserved hole;

After Sales

Herm's professional installation team will help customers install and solve problems during the installation process.

1. We will send two technical and installation engineers to guide the installation on-site.

2. After installation and debugging, we conducted operational training for the customer's workers;

3. Trained workers on how to maintain and protect;

4. Based on the product characteristics, we will develop a complete set of maintenance details for you, including how to maintain and when. Maintenance and by whom.

5. Our company’s after-sales department will regularly call Ethiopian customers to inquire about maintenance and give suggestions.

Shipment of feed production line to Ethiopia

The Ethiopian 8-12 tons per hour chicken and cattle pellet feed factory built by Herm can produce pellet nutritional feed to meet different animal species. The feed mill's main raw materials are corn, wheat, soybean meal, and other grains.

This 8-12ton per hour automatic feed pellet factory is for chicken and cattle feed pellet production, so the whole feed pellet line plant we configured for this Ethiopia customer is very special, the main feed-making machine includes a grain hammer mill, animal feed pellet mill, feed mixer, automatic bagging machine, and other auxiliary equipment.

Feed Production Process of 8-12ton per hour Feed Pellet Mill Plant

Storage of The Raw Materials

There are many different raw materials and materials in the feed, so various types of silos must be used. There are three types of silo that can be used in the feed pellet line, such as hopper silo, flat bottom silo, and galvanized silo.

Cleaning of Raw Materials

Impurities in feed raw materials not only affect the quality of feed products but also directly affect the use of feed processing equipment and the personal safety of staff. In severe cases, the entire equipment will be damaged and the smooth progress of feed production will be affected. Therefore, impurities in the feed raw materials should be removed in time.

Crushing of Raw Materials

The technological process of feed crushing is determined according to the required particle size, feed variety, and other conditions. The number of raw material crushing can be divided into primary crushing process circulating crushing process, or secondary crushing process. The combination with the batching process can be divided into the first batching and then crushing process and the first crushing and then batching process.

Batching Process

The rational design of the batching process is to correctly select the specifications and quantities of the batching metering device so that it is fully coordinated with the combination of batching feeding equipment, mixing units, and other equipment.

Mixing Process

The mixing process refers to the technological method and process of weighing the ingredients in the feed formula and then entering the mixer for uniform mixing. The mixing section requires a short mixing cycle, high mixing quality, fast discharge, low residual rate, good airtightness, and no dust spillage.

Pelleting Process

The pelleted feed obtained by compacting and extruding a single raw material or compound mixture by mechanical action is called feed pelleting. The purpose of pelleting is to use the heat, moisture, and pressure in the pelleting process to pelletize the feed that is finely divided, easily dusty, poorly palatable, and difficult to transport.

Cooling Process

During the pelleting process, when the pellet feed comes out of the feed pellet machine, the water content reaches 16%-18%, and the temperature is as high as 75°C-85°C. It will also cause adhesion and mildew during storage. The moisture must be reduced to below 14%, the temperature must be below 8°C higher than the air temperature, and cooling is required.

Crumbling Process

In the production process of the feed pellet mill, in order to save electricity, increase productivity, and improve quality, the material is often made into a certain size of pellets and then crushed into qualified products according to the size of the feed pellets.

Screening Process

After the pellet feed is processed by the crushing process, some unqualified materials such as powder will be produced. Therefore, the crushed pellet feed needs to be sieved into a product with neat particles and uniform size.

Packaging Process

After weighing, put the finished product into the packing scale and pack it. During this process, the package should be calibrated until the package weight standard is met.

Livestock plays an important role in the Ethiopian economy. 51% of Ethiopia's land area is grassland, with huge potential for livestock production. Due to the lack of livestock production technology, the slow pace of livestock and poultry breed improvement, the unreasonable layout of livestock breeding structures, and the lack of market links such as marketing, processing, and value-added services, the development of the livestock industry has been greatly restricted. The development of this potential has slowed down the development of the livestock industry. In 2019, Ethiopia’s Ministry of Finance (MoF) approved the import of duty-free animal feed. It can be seen that Ethiopia has a huge demand for feed. We will also continue to provide high-quality services and guidance to our customers.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: info@hermmachinery.com

Whatsapp: 0086 18037508651

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd will also participate in AGROWORLD...

25-10-28

Ethiopia’s growing livestock sector, particularly in sheep and goat farming, has created a substantial demand for high-quality animal feed. With t...

24-11-12Let us be your solutions source.