Herm Machinery will go to ETHIOPEX – Ethio Poultry Expo 2025

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

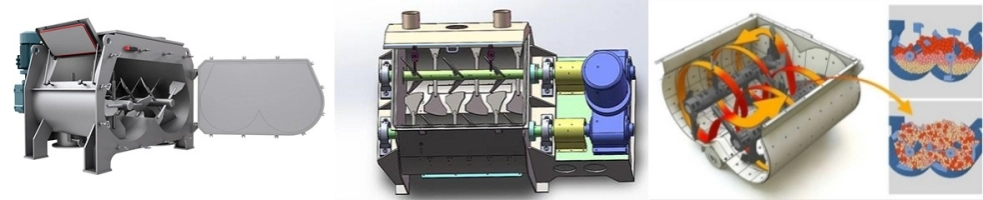

25-10-29The SLHS Series Double-Shaft Paddle Feed Mixer, developed by Henan Herm Machinery Co., Ltd., is a high-efficiency, energy-saving, and precision mixing solution for feed production. It is widely used in livestock, poultry, aquaculture, and ruminant feed processing lines and is also suitable for powder or granular materials in the grain, oil, food, and chemical industries. Featuring an innovative "W"-shaped trough and counter-rotating twin paddle shafts, the mixer achieves fast, uniform, and gentle mixing. It prevents material layering and excessive shear, ensuring product uniformity and integrity.

Make a Quick Inquiry Now !The SLHS mixer can be optionally equipped with multiple liquid spraying systems for the addition of fats, syrups, enzymes, or nutritional liquids. Its easy-cleaning design and reliable performance make it a top choice for modern feed plants.

Each batch completes in 1.5–2 minutes (filling: 20–30s, mixing: 40–60s, discharging: 10–20s), greatly increasing productivity.

✅ 2. Uniform Mixing, Stable Performance

The mechanical fluidization principle ensures homogeneous mixing without layering or segregation. Coefficient of variation (CV) ≤ 5%.

✅ 3. Gentle Processing, Material-Friendly

Low shear during mixing makes it suitable for fragile, lightweight, or fibrous materials, preserving structural integrity.

✅ 4. Energy Saving, Low Operating Costs

Energy consumption is reduced by over 15% compared to conventional mixers, with fewer wear parts and lower maintenance.

✅ 5. Easy Cleaning and Maintenance

Equipped with side inspection doors and observation windows, allowing easy cleaning and quick batch changeover with no residue.

✅ 6. Flexible Liquid Addition

An optional multi-point liquid spraying system ensures even distribution, avoiding clumping and improving liquid absorption efficiency.

✅ 7. Compact Structure, Small Footprint

Ideal for flexible layout in both new and retrofit projects. Easy installation and user-friendly operation.

✅ 8. Reliable Scale-Up to Production

Mixing results can be consistently scaled from lab tests to full production, maintaining performance stability.

The SLHS Double-Shaft Paddle Mixer features two symmetrically arranged paddle shafts rotating in opposite directions within a “W”-shaped mixing chamber. One shaft pushes the material counterclockwise along the wall, while the other performs a lateral throwing motion. At the intersection of these two flows, a temporary “Zero Gravity Zone” forms. In this zone, materials are suspended in midair, undergoing rapid tumbling, shearing, and diffusion, resulting in a comprehensive, high-speed, and uniform mixing process. Regardless of the material’s shape, particle size, or density, it can be uniformly mixed in a very short time.

The SLHS Series Double Shaft Paddle Mixer is renowned for its efficient, uniform, and gentle mixing capabilities, making it highly versatile across various industries. With flexible configuration options and excellent adaptability, it performs exceptionally well in the following application scenarios:

✅ Feed Industry

Mixing of livestock, ruminant, aquafeed premises, and compound feeds

Supports the addition of oil, enzymes, trace elements, antibiotics, and other liquid or powder components

Ensures uniform blending, enhancing the quality of subsequent pelleting or tabletizing processes

✅ Grain & Food Industry

Mixing of starch, milk powder, protein powder, flavorings, food additives, etc.

Can be designed to meet GMP or food-grade standards, with optional stainless steel liners and automatic cleaning systems

✅ Chemical Industry

Mixing of additives, compound fertilizers, dry powder coatings, pesticide carriers, etc.

Capable of homogeneous blending without segregation; suitable for adding viscous or volatile liquid ingredients

✅ Building Materials Industry

Blending of dry mortar, putty powder, tile grout, cement-based materials, etc.

Designed for high-throughput batch mixing, fast discharge, and enhanced wear resistance

✅ Other Industries

Applicable to pharmaceuticals, feed additives, new materials, environmental absorbents, and more

Custom solutions available, including sealing, explosion-proof, vacuum, or pressurized mixing configurations

Q1: What types of materials is the double-shaft mixer suitable for?

A: It is suitable for dry powder, granular, and fibrous materials, widely used in feed, food, and chemical industries. Supports liquid additions like oils, syrups, and enzyme preparations.

Q2: What is the typical mixing time?

A: Each batch takes about 1.5 to 2 minutes. Time may vary based on material characteristics.

Q3: Can liquids be added? Will it cause clumping?

A: Yes, optional multi-point atomizing nozzles ensure uniform spray distribution and prevent localized clumping.

Q4: How uniform is the mixing?

A: Mixing uniformity is ensured with CV ≤ 5%, meeting high-standard production requirements.

Q5: Is it easy to clean?

A: Yes, equipped with quick-open doors and access ports for easy cleaning and maintenance, preventing cross-contamination.

Q6: Is customization available?

A: Yes, we offer customized designs based on your needs, including liquid spraying systems, heating features, material inlets, and control systems.

✅ Case 1: 60,000 Tons/Year Livestock & Poultry Feed Plant

Configuration: 1 unit of SLHS1.0 Double-Shaft Paddle Mixer

Results: Reduced mixing cycle to 90 seconds, increased mixing uniformity by 20%, stable operation, and significantly improved overall line efficiency.

✅ Case 2: 100,000 Tons/Year Ruminant Feed Line

Configuration: 1 unit SLHS2.0 Large Mixer + Dual Liquid Spraying System

Results: Supports molasses and oil addition, uniform mixing, stable finished product quality, highly praised by the client.

✅ Case 3: Premix Feed Production Line

Configuration: 1 unit SLHS1 Premix Feed Mixer and 1 unit SLHS1 Feed Mixer

Results: It improves the overall production efficiency of the entire line, ensures uniform distribution of nutrients in the premix, and enables high-quality premix production.

| Model | Mixer Time(sec/batch) | Capacity(kg/batch) | Main Motor Power(kW) |

| SLHS1 | 60-120 | 500 | 11 |

| SLHS2 | 60-120 | 1000 | 18.5 |

| SLHS4 | 60-120 | 2000 | 30 |

| SLHS7 | 60-120 | 3000 | 45 |

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd will also participate in AGROWORLD...

25-10-28

Ethiopia’s growing livestock sector, particularly in sheep and goat farming, has created a substantial demand for high-quality animal feed. With t...

24-11-12Let us be your solutions source.