Herm Machinery will go to ETHIOPEX – Ethio Poultry Expo 2025

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

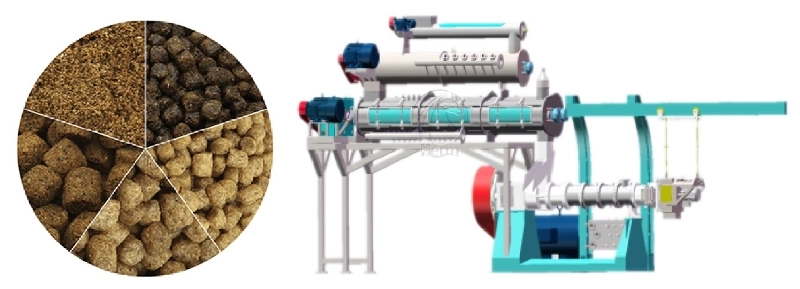

25-10-29The Single-Screw Aquatic Feed Extruder is a high-performance extrusion system designed to convert a wide range of raw materials into premium-quality aquatic feed pellets. It is widely used in producing feed for fish, catfish, tilapia, shrimp, crabs, and other aquatic species. This dry-type floating fish feed machine is ideal for small—to medium-sized fish farms and feed processing plants.

The extruder supports both floating and sinking feed production and can also process pet food, full-fat soybeans, and other specialty feeds. With a robust structure, advanced components, and energy-efficient design, this machine offers excellent durability, versatility, and performance.

✅ Versatile Feed Production

Capable of producing various types of feeds including: Floating fish feed, Sinking aquatic feed, Pet food, Full-fat soybean meal

✅ High Output Capacity

When producing Φ3.0mm tilapia feed, the machine delivers an output of 5.0–5.5 tons/hour, making it suitable for commercial operations.

✅ Advanced Material & Durability

Uses innovative wear-resistant materials, extending the lifespan of vulnerable components by 2–3 times. Screw service life reaches 8000–10,000 tons of feed.

✅ High-Precision Extruder Chamber

Constructed with reinforced strength to prevent deformation of the jacket or loosening of the wear-resistant bushing. Supports both heating and cooling operations for precise control.

✅ Modular Screw & Barrel Design

A flexible combination of chamber and single-screw allows easy adjustment and structural change. Convenient for switching between different feed types and raw materials.

✅ Floating Time Control

Extrusion degree can be adjusted to regulate floating time in water, ideal for different species’ feeding behavior.

✅ Energy Efficient Operation

Optimized design helps reduce power consumption and lowers the overall cost of feed production.

✅ Fish Feed Processing Line

Used in large tilapia farms to produce floating pellets with uniform shape and high digestibility.

✅ Shrimp and Crab Feed Plants

Supports the production of slow-sinking feed with optimal water stability for shrimp and crab farming.

✅ Pet Food Production

Produces various pet food shapes and formulations using different dies and recipes.

✅ Soybean Extrusion

Used in oilseed processing plants to produce full-fat soybean meal with enhanced digestibility.

✅ Q1: What type of feed can this extruder produce?

A: It can produce floating and sinking aquatic feeds, pet food, full-fat soybean meal, and more.

✅ Q2: Is it suitable for large-scale operations?

A: Yes, especially when producing 3.0mm tilapia feed, the capacity reaches 5.0–5.5 tons/hour.

✅ Q3: Can I adjust the floating time of the pellets?

A: Yes, the floating time can be adjusted by modifying the extrusion degree.

✅ Q4: How long do the key components last?

A: The screw can last up to 8000–10,000 tons of feed thanks to wear-resistant materials.

✅ Q5: Is the extruder easy to maintain?

A: Yes, with modular design and durable materials, it is easy to clean, replace, and maintain.

✅ Q6: Can it be customized for different materials or feed types?

A: Absolutely. The modular screw and barrel design allow flexible combinations for various materials and feeds.

The Single-Screw Aquatic Feed Extruder from Henan Herm Machinery offers a powerful, efficient, and flexible solution for producing high-quality aquatic feed and pet food. Its advanced material construction, customizable screw system, and user-friendly operation make it a vital tool for modern feed production. For more details, technical support, or to request a quotation, please contact us today.

| Model | Main Motor Power(kW) | Feeding Power(kW) | Single-shaft Conditioner Power(kW) | Capacity(t/h) |

| H135 | 90 | 2.2 | 4 | 1-2 |

| H165 | 160 | 2.2 | 4 | 3-5 |

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd will also participate in AGROWORLD...

25-10-28

Ethiopia’s growing livestock sector, particularly in sheep and goat farming, has created a substantial demand for high-quality animal feed. With t...

24-11-12Let us be your solutions source.