Herm Machinery will go to ETHIOPEX – Ethio Poultry Expo 2025

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

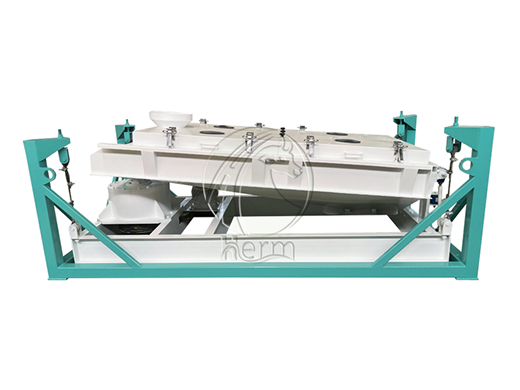

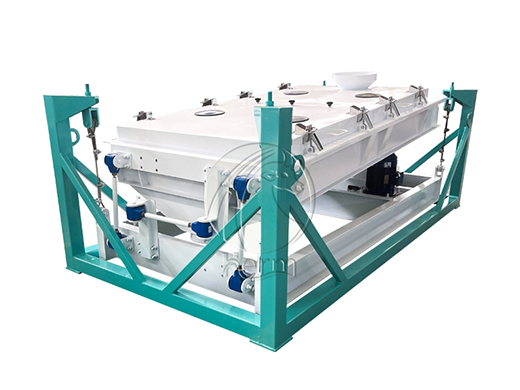

25-10-29The Rotary Grading Sifter, also known as a vibrating screening classifier, is specially designed for grading and separating pellets and granules. It plays a crucial role in modern pellet production lines by improving product quality, reducing fines, and enabling efficient material recirculation.

With a robust design and versatile application, it is widely used in feed mills, biomass fuel plants, organic fertilizer lines, wood pellet factories, pet litter production, and other bulk material processing industries.

✅ Pellet Classification in Production Lines

Used after the pelletizing process, the rotary sifter efficiently separates qualified pellets from fines and oversized particles. This ensures a consistent size range for packaging or storage.

✅ Pre-Cleaning Before Grinding

In grain and feed processing, the sifter removes large impurities from raw materials before they enter grinding machines like hammer mills or roller mills, reducing wear and improving grinding efficiency.

✅ Powder Recovery & Recycling

Unqualified fine particles collected after pelletizing can be redirected to pellet mills for reprocessing, minimizing waste and improving yield.

✅ Broad Industry Use

Besides feed and biomass industries, the sifter is also widely used for material screening in food processing, chemical manufacturing, sugar refining, mining, paper production, and more.

✅ Flexible Sieve Options

The sieves are interchangeable and available in a wide range of mesh sizes to accommodate different material characteristics and classification requirements.

✅ Low Noise and Vibration

Elastic composite material supports and vibration-dampening structure reduce operational noise and machine vibration, promoting a quieter and more stable working environment.

✅ Efficient Eccentric Drive Mechanism

The sifter employs a V-belt-driven eccentric balancing system and horizontal gyratory body, resulting in highly effective screening motion with minimal energy consumption.

✅ Compact and Easy to Maintain

With vibration motors mounted at the rear, the machine saves installation space. Its quick-release sieve press mechanism allows fast sieve changes and easy maintenance access.

✅ Adjustable Amplitude Design

Operators can adjust the vibration amplitude to optimize screening performance based on specific material requirements, offering high flexibility in production control.

✅ Anti-clogging Design

Smooth interior discharge chute prevents material accumulation and cross-contamination, ensuring hygienic and uninterrupted processing.

✅ Q1: What materials can be processed with the rotary grading sifter?

A1: It is suitable for granular and pelletized materials such as feed pellets, wood pellets, biomass, grain, chemical granules, and more.

✅Q2: Can it be used in dusty or moist environments?

A2: Yes. The sifter features dust-sealed enclosures and smooth discharge channels to maintain clean operation in dusty conditions.

✅Q3: How easy is it to clean or replace the screens?

A3: Very easy. The bolt-connected sieves and quick-release pressing system allow rapid disassembly and cleaning without special tools.

✅Q4: Can the machine be integrated into an existing pellet line?

A4: Absolutely. It supports both standalone operation and full integration into automated pelletizing systems.

✅Q5: Is the amplitude adjustable?

A5: Yes. Operators can fine-tune the vibration amplitude for optimal screening efficiency across different materials.

✅ Case 1: 20T/H Goat and Cow Feed Plant in Saudi Arabia

The plant integrated our rotary grading sifter after the pelletizing stage. This improved the classification of goat and cow feed pellets, significantly reducing powder content and ensuring quality for end-users.

✅ Case 2: 8-10T/H Chicken Feed Pellet Line in Mexico

The plant integrated our rotary grading sifter after the pelletizing stage. This improved the classification of 4.0mm chicken pellets, significantly reducing powder content and ensuring quality for end-users.

✅ Case 3: 10T/H Cattle Feed Pellet Line in Ethiopia

The plant integrated our rotary grading sifter after the pelletizing stage. This improved the classification of pig feed pellets, significantly reducing powder content and ensuring quality for end-users.

| Model | Power(kw) | Pellet Capacity(t/h) | Power(kW) |

| SFJH80*2 | 2.2 | 5-8 | 3-6 |

| SFJH130*2 | 2.2 | 8-13 | 6-10 |

| SFJH100*2 | 3.0 | 10-15 | 8-13 |

| SFJH150*2 | 3.0 | 15-18 | 12-16 |

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd will also participate in AGROWORLD...

25-10-28

Ethiopia’s growing livestock sector, particularly in sheep and goat farming, has created a substantial demand for high-quality animal feed. With t...

24-11-12Let us be your solutions source.