HERM MACHINERY

The feed pellet machine is a core component in feed mills, playing a crucial role in both standalone operations and integrated feed pellet production lines. This multifunctional feed pellet maker is capable of producing a wide variety of animal feeds, meeting the nutritional needs of different livestock. Whether it's formulating feed for ruminants like cattle, sheep, and camels, or providing customized feed for livestock such as horses, pigs, and rabbits, it excels in all applications. Furthermore, the machine is also suitable for poultry feed production, including feeds for chickens, ducks, geese, and more.

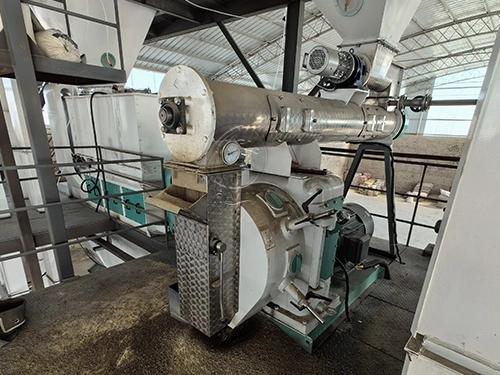

Herm Machinery offers a premium commercial feed pellet machine, designed for precision feed pellet production. This machine features a high-precision gear drive system and ring die mechanism, ensuring superior performance. The combination of a stainless steel conditioner and a frequency control system further enhances the machine's efficiency and stability. It is equipped with high-quality bearings to ensure long-term reliable operation with low noise levels. The machine can operate independently and comes with an electric control cabinet for easy adjustment and monitoring.

✅ 1. Efficient Production and Precise Control

With advanced ring die design and high-precision gear drive technology, the machine produces uniform feed pellets efficiently and steadily. The optimized conditioning system enhances the material's hydration, ensuring the pellets achieve optimal hardness and density, thus maximizing raw material utilization and reducing energy waste, as well as high-nutrition poultry and livestock feeds. This makes it highly flexible, meeting the diversified production needs of farms and significantly increasing production flexibility.

✅ 2. High Adaptability, Meeting Diverse Needs

The machine is capable of handling various feed materials, catering to the production of different animal feeds. It can efficiently process grains (wheat, corn), fibrous materials like hay and straw, as well as high-nutrition poultry and livestock feeds. This makes it highly flexible, meeting the diversified production needs of farms and significantly increasing production flexibility.

✅ 3. Low Noise and High Stability

The use of high-quality bearings combined with a precision transmission system ensures that the machine operates quietly and steadily. Even with prolonged continuous operation, the machine maintains stable performance, reducing downtime and machine failure. This is crucial for improving production continuity and efficiency.

✅ 4. Energy-Efficient and Environmentally Friendly Design

The optimized conditioning system and variable frequency technology significantly reduce energy consumption while improving pellet quality. Efficient heat utilization and energy-saving technologies help minimize energy waste during the raw material heating and compression process, reducing production costs. The energy savings and reduced emissions contribute to environmentally friendly production, in line with modern ecological requirements.

✅ 5. Easy Maintenance and Safe Operation

The design considers the long-term maintenance needs of the machine, making it easy to clean and maintain. Major components like the ring die, gears, and bearings are easily detachable and replaceable. Regular inspection and lubrication ensure the machine remains in optimal condition. Additionally, safety devices are installed to prevent accidents, ensuring operator safety.

The working principle of the feed pellet machine relies on high-precision gear-driven and ring die compression technology. Materials enter the machine via the feeding port, where they are pre-processed by the conditioner to enhance the moisture and temperature of the raw materials. The treated material is then pressed into pellets under high pressure and temperature using the ring die. Finally, the pellets are cooled and shaped by the cooling system, ensuring that the pellets retain optimal nutritional content and ideal hardness after drying and cooling.

The feed pellet machine is suitable for all types of farms, especially medium to large-scale farms. It is widely used in the production of feed pellets, suitable for processing various raw materials such as grains (wheat, corn, rice, etc.), as well as fibrous materials like hay and straw. Whether for traditional feed mills or modern farms, this machine provides efficient and stable production support for the livestock industry.

✅ Q1: What is the production capacity of the feed pellet machine?

A1:The production capacity of the feed pellet machine varies depending on the model, with a range from 1.5 tons per hour to 40 tons per hour. The actual output will also depend on factors such as the type of raw materials, pellet size, and machine settings. Generally, the machine maintains high-efficiency production, suitable for farms and feed mills of various scales.

✅ Q2: What raw materials can the machine process?

A2: The feed pellet machine is capable of processing various feed raw materials, including but not limited to grains (such as wheat, corn, rice), legumes, straw, hay, and other fibrous materials. This makes the machine versatile in the feed industry, suitable for poultry feed, ruminant feed, and pig feed production.

✅ Q3: Is the machine suitable for producing feed for different types of animals?

A3: Yes, this machine is highly flexible and can produce feed suitable for different types of animals. For example, by adjusting the pellet size and formula, it can produce coarse feed for ruminants such as cattle and sheep, and finer pellets for poultry (such as chickens and ducks) and pigs.

✅ Q4: How does the machine ensure feed quality?

A4: The machine uses high-precision gear drive and ring die compression technology to form pellets under controlled temperature and pressure. The efficient conditioning system ensures even mixing and adequate hydration of the raw materials, guaranteeing strong, uniform feed pellets. Additionally, the nutritional content of the pellets is preserved throughout the process.

✅ Q5: Is the machine easy to operate and maintain?

A5: The machine is designed with user-friendliness in mind, making operation simple. The electrical control system provides automated control, and operators only need to perform basic settings and monitoring. Maintenance is straightforward, with key components like the ring die and gears being easy to disassemble for cleaning. Regular checks and lubrication keep the machine running efficiently. Comprehensive operation manuals and training are also provided to help operators get up to speed quickly.

✅ Q6: What is the energy efficiency of the machine?

A6: The feed pellet machine is highly energy-efficient. The variable frequency control system, adjusts the working speed based on production needs, optimizing energy consumption. Additionally, the efficient conditioning system reduces energy waste during the production process, improving overall production efficiency and final product quality.

✅ Q7: Can the machine handle batch production?

A7: Yes, the machine is designed for batch production, particularly in high-demand, continuous production scenarios. Its high production capacity and automated control system make it an ideal choice for large-scale feed production plants.

✅ Case 1: Large-scale Pig Farm Feed Production

At a large-scale pig farm with a yearly capacity of several thousand pigs, the feed demand is enormous, and feed quality must meet high standards. The farm uses the feed pellet machine to produce feed for different pig breeds. The machine efficiently processes common raw materials such as soybean meal, corn, and wheat bran, precisely controlling pellet size and hardness to meet the nutritional needs of pigs.

Production Results:

The machine produces over a thousand tons of high-quality feed per day, meeting large-scale production needs.

Raw material utilization is significantly improved, reducing feed material waste by over 15%.

The machine remains stable and efficient even after long hours of continuous operation, reducing downtime and maintenance costs.

Feed Quality:

The pellets produced have moderate hardness, improving digestibility and growth rates in pigs.

Pellet uniformity reduces feed separation during storage and transport, avoiding waste.

Environmental Improvements:

The machine's low-noise operation enhances the work environment and reduces noise pollution for employees.

✅ Case 2: Multi-species Poultry Farm Application

At a large poultry farm that raises chickens, ducks, and geese, the feed requirements vary by species, with each needing a different formula and pellet size. The feed pellet machine's versatility allows the farm to easily switch between different feed formulas, producing high-quality pellets for each poultry type.

Production Flexibility:

The machine can quickly switch between different feed formulas to meet the nutritional needs of chickens, ducks, and geese.

For chickens with higher protein requirements, the machine adjusts the feed composition to produce high-protein pellets; for ducks and geese, pellet size is adjusted to accommodate their feeding and digestion habits.

Feed Quality:

The pellets are uniform, ensuring that each bird receives the necessary nutrients.

Fine control over pellet size reduces waste and improves digestion rates.

Efficiency Gains:

Automation increases production efficiency, reducing human labor and the risk of manual errors.

The high efficiency of the machine speeds up production to meet the farm's high demand for feed.

✅ Case 3: Grass and Straw Processing Application

At an intensive agriculture production base, grass and straw are used as raw materials for feed. This farm primarily raises ruminants such as cattle, sheep, and camels, which require large amounts of roughage.

Raw Material Conversion Efficiency:

The feed pellet machine effectively converts grass and straw into high-density, nutrient-rich pellets, improving feed digestibility.

For ruminants, these pellets enhance fiber utilization and promote better digestion and absorption.

Cost Reduction:

The use of local agricultural by-products significantly lowers feed costs and reduces reliance on purchased feed.

The stable quality of pellets ensures that animals receive balanced nutrition, avoiding slow growth or health issues due to nutritional imbalances.

Environmental Benefits:

Using local grass and straw resources increases resource utilization efficiency and reduces environmental pollution caused by waste materials.

The Herm Machinery Feed Pellet Machine is an advanced solution for animal feed production, offering high efficiency, flexibility, and reliability for large-scale and diversified farms. With its energy-efficient operation, user-friendly design, and adaptability to different raw materials and feed types, it is the ideal choice for modern feed production. Whether producing feed for poultry, ruminants, or pigs, this machine ensures high-quality pellets, cost-effective production, and environmental sustainability.

Make a Quick Inquiry Now !| Model | Main Motor Power (kW) | Conditioner Power (kW) | Mold Dia(mm) | Feeder Power (kW) | Finished pellets size (mm) | Yield (t/h) |

| HMLH250 | 22 | 1.5 | 250 | 0.75 | 1.5-12 | 1.5-2.2 |

| HMLH320 | 37 | 2.2 | 320 | 1.5 | 1.5-12 | 2-4 |

| HMLH350 | 55 | 2.2 | 350 | 1.5 | 1.5-12 | 2-6 |

| HMLH400 | 90 | 3 | 400 | 1.5 | 1.5-18 | 3-8 |

| HMLH420 | 110 | 5.5 | 420 | 1.5 | 1.5-18 | 4-12 |

| HMLH508 | 160 | 7.5 | 508 | 2.2 | 1.5-18 | 4-18 |

| HMLH558 | 180/200 | 11 | 558 | 2.2 | 1.5-18 | 15-25 |

| HMLH678 | 220/250 | 11 | 678 | 2.2 | 1.5-18 | 20-30 |

| HMLH768 | 280/315 | 11 | 768 | 2.2 | 1.5-18 | 30-35 |

| HMLH858 | 280/315 | 15 | 858 | 2.2 | 2.0-18 | 35-40 |