Herm Machinery will go to ETHIOPEX – Ethio Poultry Expo 2025

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29The H Series Twin-Screw Feed Extruder is engineered to produce a wide variety of floating, sinking, and slow-sinking aquatic feeds. Designed to handle complex and demanding formulations, it produces high-quality feed pellets for species like California seabass and grouper. With the ability to process small particle sizes down to 0.6mm and handle low-starch, high-protein, and high-fat recipes, this extruder is a perfect choice for modern, high-performance aquaculture.

The system can be equipped with vacuum extraction, pressure density control technologies, and a fully automated control system to ensure operational stability and consistent product quality.

✅ High Productivity with Low Energy Consumption

20:1 length-to-diameter ratio for optimal extrusion.

Stabilized screw configuration boosts output.

Productivity surpasses similar domestic models by 15–20%.

Energy consumption is as low as 23–25 kWh/ton.

✅ Broad Processing Range & Lower Production Costs

Capable of producing floating, sinking, and slow-sinking feeds.

Processes fine particles: 0.6mm (floating) and 0.8mm (sinking).

Handles complex formulations like low-starch, high-protein, and high-fat.

Enhances feed intake, digestion, and growth performance.

✅ Excellent Pellet Uniformity

Full kneading screw technology and dual-die discharge system.

High-precision screws and liners ensure uniform pressure and shape consistency.

✅ Enhanced Puffing & Maturation

Triple-axis conditioner with water-steam co-injection.

Sectional zoning using EDEM simulation technology.

Optimized blade arrangement for better material filling and mixing.

Extended effective conditioning time improves gelatinization and maturation.

✅ Stable, Safe, and Reliable Operation

Built to EU and US mechanical standards.

Gearbox with 5-level high-precision gears.

Uses branded bearings and oil seals for smooth transmission.

New wear-resistant alloy screws with a lifespan exceeding 50,000 tons.

✅ Aquaculture Feed Plants: Ideal for producing floating and sinking feeds for freshwater and marine species.

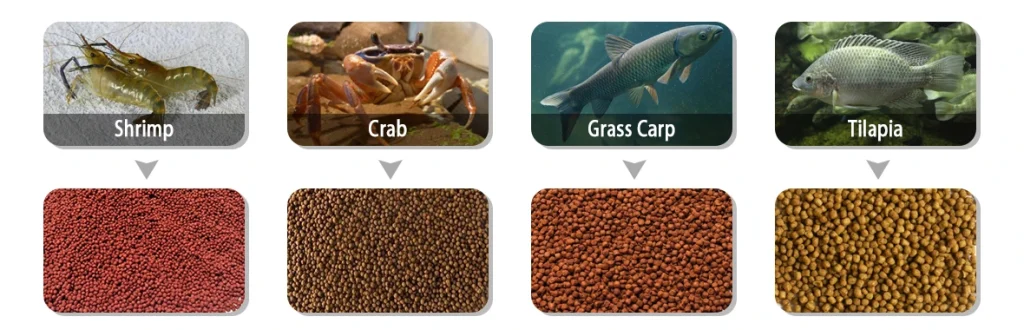

✅ High-End Feed Production: Suitable for low-starch, high-protein feed for seabass, grouper, shrimp, and other valuable species.

✅ Research Institutions: Perfect for R&D and pilot-scale production requiring flexibility and consistency.

✅ Pet Food Industry: Capable of producing uniform, nutritious pet food pellets.

✅ Q1: What types of feed can the twin-screw extruder produce?

A: It produces floating, sinking, and slow-sinking aquatic feed pellets, as well as specialized feeds with low-starch and high-protein content.

✅ Q2: What is the smallest pellet size it can produce?

A: It can produce floating pellets as small as 0.6mm and sinking pellets as small as 0.8mm.

✅ Q3: How energy-efficient is the machine?

A: It consumes only 23–25 kWh per ton of feed, making it highly energy-efficient.

✅ Q4: Is the machine suitable for complex formulas?

A: Yes, it is specially designed to handle low-starch, high-fat, and high-protein formulations.

✅ Q5: What is the service life of the main components?

A: The wear-resistant screws offer a lifespan of over 50,000 tons.

✅ Q6: Can it be integrated into a fully automated production line?

A: Yes, the extruder can be paired with vacuum systems, density controllers, and a fully automatic control system.

| Project | H156 | H176 | Note |

| Main engine power(kW) | 315/355 | 560/630 | Variable frequency control |

| Feeder power(kW) | 3.0 | 5.5 | Variable frequency control |

| Three-axis tempering machine power(kW) | 15+37 | 15+37/18.5+45 | |

| Cutting motor power(kW) | 7.5 | 11 | Variable frequency control |

| length-to-diameter ratio | 20:1 | 20:1 | |

| Capacity(t/h) | 10~12 | 15~20 | floating material templateΦ4.0 |

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd will also participate in AGROWORLD...

25-10-28

Ethiopia’s growing livestock sector, particularly in sheep and goat farming, has created a substantial demand for high-quality animal feed. With t...

24-11-12Let us be your solutions source.