Herm Machinery will go to ETHIOPEX – Ethio Poultry Expo 2025

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29Henan Herm Machinery Co., Ltd. is a leading provider of comprehensive solutions in the feed industry, dedicated to offering full, customized feed engineering services for feed manufacturers. Our 15-25T/H feed production line is specifically designed for large-scale feed mills, farms, and animal feed suppliers, capable of efficiently processing a wide range of animal feed, including poultry, livestock, fish, and pet feeds. This production line optimizes the entire feed production process through intelligent technology and high-efficiency equipment, reducing costs, improving production efficiency, and enhancing product quality.

Advanced Equipment for Optimized Production Efficiency

The core equipment in this production line includes: Hammer Mill, Feed Pellet Machine, Twin-Shaft Feed Mixer, Counter-Flow Pellet Cooler, Pellet Crusher, Pulse Dust Collector, Vibrating Sieve, and Automatic Packing Machine. These devices work in perfect synergy to ensure that each step in the production process—from raw material mixing, transportation, and feeding to granulation—is carried out efficiently and steadily. Our design philosophy emphasizes process optimization, reduced energy consumption, and enhanced production efficiency.

Henan Herm Machinery Co., Ltd. offers a full-service, one-stop feed production line solution, covering the entire process from project planning to production startup. Whether it’s constructing a new feed factory or upgrading an existing one, we provide tailored professional solutions to ensure smooth project execution and maximize production benefits. Our goal is to enhance the automation and modernization of the production line, reduce operational costs, and improve product quality.

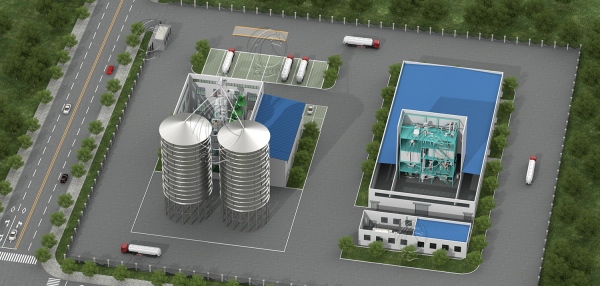

Comprehensive Project Planning and 3D Design

For both new feed factories and upgrades to existing plants, we provide scientifically designed and customized engineering solutions, including detailed process design and 3D modeling. Early in the project, we used 3D designs to visualize each production line stage, ensuring a smooth production process with a rational equipment layout to maximize production efficiency.

Factory Construction and Custom Infrastructure Solutions

We offer customized solutions for factory construction, including steel structure buildings, steel silos, drying towers, and other necessary infrastructure. For new feed plants, we design factory buildings based on production requirements, while for factory upgrades, we offer practical solutions that ensure the building meets production standards and utilizes space efficiently.

Precise Equipment Selection, Configuration Optimization, and Technological Upgrades

We provide optimal equipment configurations and technical upgrade solutions, whether for new feed factory equipment selection or upgrading existing plant equipment. Based on your specific production needs, we recommend the most suitable equipment and configure it for efficient, stable operation. Our focus is on energy-saving, cost-reduction, and smart upgrades, elevating the modernity of your production line.

Professional Installation, Debugging, and Project Implementation

Our professional installation team ensures fast, accurate installation and debugging of equipment, enabling the new feed factory to begin production in the shortest time possible. For factory upgrades, we ensure a smooth transition, minimizing downtime. We consider site conditions and production requirements during installation to ensure efficient and stable operation in the long run.

Systematic Employee Training and Technical Support

We offer comprehensive training to ensure that staff fully understand the operation of equipment, including usage, standard operating procedures, and troubleshooting techniques. This training ensures smooth production processes. Additionally, our technical team provides ongoing support to resolve any issues during operation, ensuring the feed production line runs efficiently at all times.

Complete After-Sales Service and Long-Term Technical Support

We provide timely after-sales service to ensure the long-term, stable operation of your equipment. Regular equipment inspections and maintenance, as well as continuous technical support, help maintain the competitiveness of your production line. We also offer ongoing technological upgrades and optimization services to ensure your equipment remains industry-leading.

Environmental Protection and Intelligent Upgrades

In both new and upgraded feed production lines, we focus on incorporating environmental protection and smart technology. Our production facilities meet modern environmental standards to minimize the environmental impact during production. Additionally, we provide smart upgrade options, including automation control systems and data monitoring systems, to improve production efficiency and optimize processes.

Raw Material Storage: Utilizing various storage facilities such as flat-bottom silos, cone silos, and bucket elevators ensures safe and clean storage of raw materials.

Raw Material Cleaning: Removing impurities from raw materials ensures feed quality and normal equipment operation.

Grinding Process: Raw materials are ground according to specific requirements to ensure that the particle size meets production standards.

Ingredient Proportioning and Mixing: The raw materials are precisely proportioned and mixed in a twin-shaft mixer to ensure uniformity for the best formulation.

Pelletizing: Using a feed pellet machine, the mixed materials are compressed into pellets, ensuring they are compact and easy to transport.

Cooling and Crushing: The pellet cooler reduces the temperature and humidity of the pellets, making them suitable for storage and transportation. After cooling, the pellets are crushed to meet various animal feed specifications.

Screening and Packaging: The vibrating sieve removes unqualified pellets, ensuring uniformity and quality. Finally, the pellets are weighed and packaged by an automatic packing machine, making them ready for transport and sale.

Wide Application: Flexible Production Formula to Meet Diverse Needs

Our 15-25T/H feed production line is highly versatile and can be used to produce various types of animal feed, including:

The production line is flexible and can adjust production formulas and pellet specifications to meet the needs of different animals, adapting to market changes.

Low Investment and Installation Cost:

Our feed production line design is compact, maximizing factory space utilization and reducing construction and installation costs.

High Efficiency and Low Operating Cost:

With an automated control system, manual intervention is minimized, requiring only 2-3 operators to complete production tasks. This greatly reduces labor costs, improves efficiency, and increases profitability.

Diverse Raw Materials and Formula Support:

Our production line can handle a variety of raw materials, including corn, wheat, soybeans, and oilseed cakes. It can also adapt formulas for different animals and changing market demands.

Advanced Technology and Strong Support:

With years of industry experience and a professional technical team, we offer full technical support to ensure your production line runs efficiently and improves your production outcomes.

Customized Solutions and Continuous Optimization:

We provide tailored solutions and continuous technological upgrades to ensure your equipment stays ahead of the industry.

Choose Henan Herm Machinery Co., Ltd., and you will not only gain an efficient, energy-saving, and cost-effective feed production line but also enjoy a full range of one-stop professional services. We will assist you at every step, from design to production, ensuring smooth project implementation and offering high-quality after-sales support to maintain long-term, efficient operations. Whether it’s building a new feed factory or upgrading an existing one, we provide complete, customized solutions.

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd. will also participate in AGROWORL...

25-10-29

As a relatively well-known animal feed making machine manufacturer in China, Henan Herm Machinery Co., Ltd will also participate in AGROWORLD...

25-10-28

Ethiopia’s growing livestock sector, particularly in sheep and goat farming, has created a substantial demand for high-quality animal feed. With t...

24-11-12Let us be your solutions source.